A na-eji eriri ígwè GB 1200 × 2400 eme ihe maka nnukwu owuwu na ụlọ dị elu.

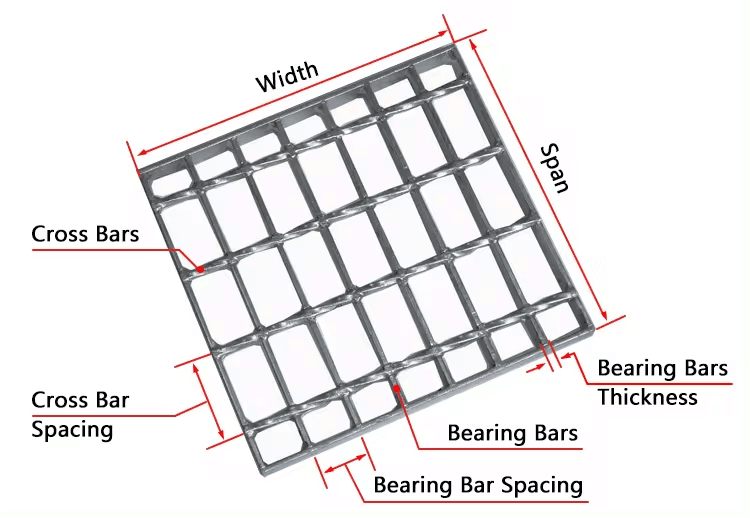

| Aha ngwaahịa | E ji ígwè mee ihe |

| Ụdị imewe | Modem |

| ihe | Ọkụ na-ekpo ọkụ, ahaziri ahazi |

| Ibu | 7-100kg |

| Ogwe Na-ebu | 253/ 255/303/325/ 405/553/655 |

| Pitch nke na-ebu mmanya | 30mm 50mm 100mm |

| atụmatụ | Ezigbo Mgbochi Nguzogide, Mgbochi Mbugharị |

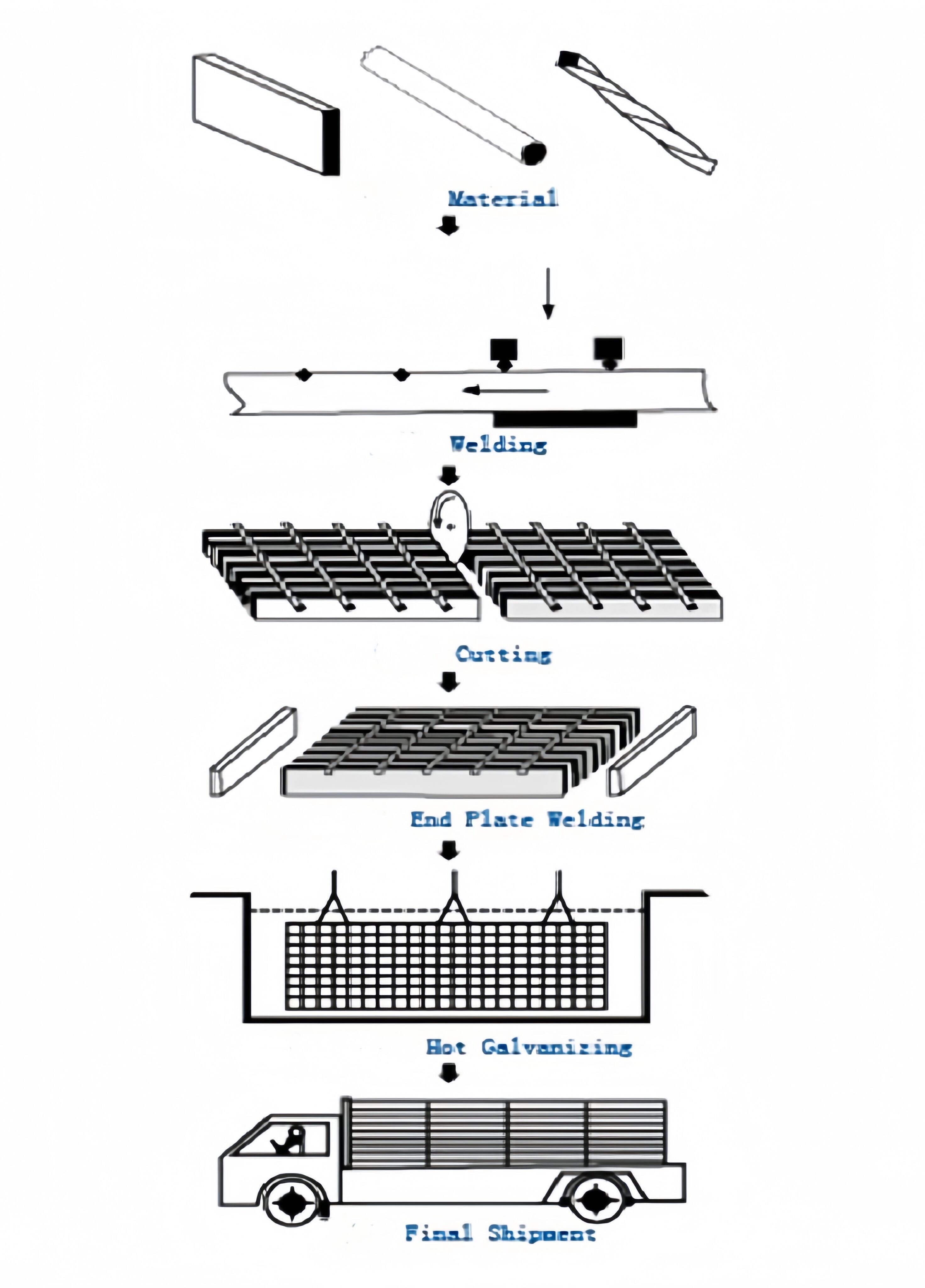

| Akụrụngwa | Igwe Galvanized Ejiri Ọkụ Mee Q235 |

| Ọkọlọtọ | Ụkpụrụ Ndị Yuropu, GB/T13912-2002,BS729,AS1650 |

| Ụzọ Weld | Ịgbado Mgbochi Nrụgide Akpaka |

| Kọlụm chaatị | ngwongwo efu n'etiti | Ebe obibi | Nkọwapụta nha dị larịị (obosara na ọkpụrụkpụ) | |||||||

| 20x3 | 25x3 | 32x3 | 403 | 20x5 | 25x5 | |||||

| 1 | 30 | 100 | G20330100 | E25230H00 | C32380F100 | G40230100 | E205/30100 | E255/307100 | ||

| 50 | G20230/50 | C253/20/50 | C2233050 | 640340100 | C205/00/50 | C255/30/50 | ||||

| 2 | 40 | 100 | 6203/401100 | 8253/40100 | E323/401100 | 640340100 | 8205/40/100 | 5255/40/100 | ||

| 50 | G20340/50 | G250/40/50 | G223/4050 | G403140/50 | 205/4/50 | G255/4050 | ||||

| 3 | 60 | 50 | G203460/50 | C25360/50 | 5253/6050 | 3403480150 | C205/60/50 | G255/60150 | ||

| Kọlụm chaatị | ngwongwo efu n'etiti | Ebe obibi | Nkọwapụta nha dị larịị (obosara na ọkpụrụkpụ) | |||||||

| 32×5 | 40x5 | 45x5 | 5045 | 55×5 | 80x5 | |||||

| 1 | 30 | 100 | G325301100 | G40530H00 | C45580100 | G50530100 | G555/30100 | E805/30/100 | ||

| 50 | G325/30/50 | C405/20/50 | G455/3050 | S505/30/50 | 55500/50 | G605/8050 | ||||

| 2 | 40 | 100 | 8325401100 | 840540100 | 455/40100 | G50540100 | 8555/40/100 | 2605/40/100 | ||

| 50 | G32540/50 | C405/40/50 | G4554050 | G505/40/50 | E555/40/50 | G605/40150 | ||||

| 3 | 60 | 50 | G225.6051 | C405/6A/50 | G4556050 | G50560/50 | 6555/6050 | G6056051 | ||

GB Steel Grating

Ọkọlọtọ: GB/T 700-2006

YB/T4001.1-2007

atụmatụ

ASTM A36 ígwè gratingA na-eji ígwè carbon dị ala emepụta ya, nke nwere ezigbo ike ịgbado ọkụ na nhazi. A maara ya maka ike dị elu ya na ikike ibu ibu pụrụ iche. Nke a na-eme ka ihe eji emechi ígwè A36 dị mma maka iji ya arụ ọrụ dị arọ n'ụlọ ọrụ mmepụta ihe, dịka ebe a na-ewu ihe owuwu, ụlọ ọrụ mmepụta ihe, na ebe a na-emepụta petrochemical. Ọ na-enye ike iguzogide mmetụta, okpomọkụ, na nchara, na-eme ka ọ dị ogologo ndụ ọbụlagodi na gburugburu ebe siri ike.

Ejiri ígwè mee iheA na-eji ígwè tee ya ihe mkpuchi zinc, nke na-enye nchebe ka mma megide nchara na nchara. Usoro galvanization ahụ na-eme ka grating ahụ dị ogologo oge, na-eme ka ọ dị mma maka nrụnye n'èzí ma ọ bụ ebe mmiri na ihe ndị na-emebi emebi na-apụta. A na-ejikarị grating galvanized eme ihe n'ebe ndị na-aga ije, sistemu mmiri mmiri, na ikpo okwu, ebe elu ya na-egbochi ịmịpụ na-agbakwụnye nchekwa ọzọ.

Isi ihe dị iche n'etiti ihe e ji ekpuchi ígwè ASTM A36 na ihe e ji ekpuchi ígwè a na-akpọ galvanized grating bụ na ihe ndị ha ji eguzogide nchara. Ọ bụ ezie na ihe e ji ekpuchi ígwè ASTM A36 na-enye ọkwa ntọala nke iguzogide nchara, ihe e ji ekpuchi ígwè a na-enye nchebe ka mma, na-agbatị ndụ ya nke ukwuu. A na-atụ aro ihe e ji ekpuchi ígwè a na-akpọ galvanized grating maka ngwa ebe mgbochi nchara dị oke mkpa.

Ngwa

Ihe e ji ekpuchi ígwè, nke bụ ngwaahịa dị iche iche ma na-adịgide adịgide, enwetawo ewu ewu nke ukwuu n'ihi ọtụtụ ojiji ya n'ọtụtụ ụlọ ọrụ dị iche iche. Ejiri ihe e ji ekpuchi ígwè ma ọ bụ efere jikọtara ọnụ mee ihe, ihe e ji ekpuchi ígwè na-enye ike pụrụ iche, nkwụsi ike, na ikike mmiri.

1. Ngalaba ụlọ ọrụ mmepụta ihe:

Ngalaba ụlọ ọrụ mmepụta ihe na-eji ihe e ji agbaji ígwè eme ihe nke ukwuu maka ike na nchekwa ya na-enweghị atụ. A na-ejikarị ya eme ala n'ime ụlọ ọrụ mmepụta ihe na ụlọ nkwakọba ihe, na-enye elu kwụsiri ike maka igwe dị arọ ma na-enye ndị ọrụ ebe ha ga-anọ. A na-ejikwa ihe e ji agbaji ígwè eme ihe maka ebe a na-adọba ụgbọala, ebe a na-ebuli elu, na ebe a na-adọba ụgbọala, na ebe a na-adọba ụgbọala, na-enye ndị ọrụ ohere ịnweta ebe dị iche iche n'ime ụlọ ọrụ ahụ.

2. Ụlọ ọrụ ihe owuwu:

N'ọrụ owuwu ụlọ, ihe eji emechi ígwè dị oke mkpa. A na-eji ya eme ihe nke ukwuu dị ka ebe a na-edebe ihe owuwu, na-enye ebe ọrụ siri ike ma dị nchebe maka ndị ọrụ nọ n'elu elu. Site na ikike ibu ibu ya dị elu, ihe eji emechi ígwè na-eme ka ndị ọrụ owuwu nwee nchekwa n'oge dị iche iche nke ọrụ ahụ. Ọzọkwa, enwere ike ịhazi ihe eji emechi ígwè ka ọ mezuo ihe achọrọ kpọmkwem, na-eme ka ọ bụrụ nhọrọ kachasị mma maka iwu ụzọ ụkwụ, steepụ, na mkpuchi mmiri n'ime ụlọ.

3. Ngalaba Njem:

N'ihi oke ike ya na ibu ya dị mma, a na-eji ihe eji emechi ígwè eme ihe n'ọtụtụ ebe n'ime ụgbọ njem. A na-ejikarị ya eme ihe maka ịmepụta ụzọ ụkwụ siri ike, nke na-anaghị amị amị na steepụ n'ebe a na-arụzi ụgbọala, ọdụ ụgbọelu, ọdụ ụgbọ okporo ígwè, na ebe a na-ebu ụgbọ mmiri. Ngwọta ndị a na-eji emechi ígwè na-eme ka nchekwa dịkwuo mma ma na-eme ka mmegharị ahụ dị irè, ọbụlagodi n'ọnọdụ ihu igwe siri ike.

4. Ụlọ ọrụ ike na mmanụ:

Ụlọ ọrụ ike na mmanụ na-adabere nke ukwuu na grating ígwè maka ịdịte aka ya na iguzogide nchara. A na-ejikarị grating ígwè eme ihe n'ụlọ ọrụ mmanụ, ụlọ ọrụ ọkụ eletrik, na ebe a na-emepụta kemịkalụ. Ọ na-eje ozi dị ka ihe ngwọta ala kacha mma, karịsịa n'ebe mmiri mmiri, kemịkalụ, na oke okpomọkụ na-ekpo ọkụ, na-ahụ na nchekwa ndị ọrụ na igbochi ihe mberede.

5. Ngwa Azụmaahịa na Nhazi Ụlọ:

E ji ígwè mee ihe na-abanyekwa n'ọrụ azụmahịa na ụlọ. Mma ya mara mma, tinyere uru ya bara uru, na-eme ka ọ bụrụ ezigbo nhọrọ maka imepụta ihe ndị mara mma, ihe mkpuchi anyanwụ, na ihe mkpuchi ịchọ mma. A pụkwara iji ihe mkpuchi ígwè mee ihe dị ka ihe nka n'obodo ukwu, na-enye ma ihe osise ma ihe bara uru.

Ngosipụta Ngwaahịa

NKWEKỌTA NA MBUPU

Nleta onye ahịa

Ajụjụ Ndị A Na-ajụkarị

1. Kedu otu m ga-esi nweta nkọwa n'aka gị?

I nwere ike izipu anyị ozi, anyị ga-azakwa ozi ọ bụla n'oge.

2.Ị ga-ebuga ngwongwo n'oge?

Ee, anyị na-ekwe nkwa inye ngwaahịa kacha mma na nnyefe n'oge. Ikwesị ntụkwasị obi bụ echiche ụlọ ọrụ anyị.

3. Enwere m ike ịnweta ihe nlele tupu iwu?

Ee, n'ezie. Ọtụtụ mgbe, ihe nlele anyị bụ n'efu, anyị nwere ike imepụta site na ihe nlele gị ma ọ bụ eserese teknụzụ.

4. Kedu usoro ịkwụ ụgwọ gị?

Oge ịkwụ ụgwọ anyị na-akwụkarị bụ 30% nkwụnye ego, ebe fọdụrụ na B/L.

5. Ị na-anabata nyocha nke ndị ọzọ?

Ee anyị nabatara nke ọma.

6. Kedu ka anyị si atụkwasị ụlọ ọrụ gị obi?

Anyị bụ ọkachamara n'azụmahịa ígwè ruo ọtụtụ afọ dịka onye na-ebunye ọla edo, isi ụlọ ọrụ anyị dị na mpaghara Tianjin, anyị na-anabata gị inyocha ya n'ụzọ ọ bụla.