Ọkpụkpọ igwe dị ike dị elu nke nwere ike imegharị Nodular nke na-agbanwe agbanwe

Nkọwa ngwaahịa

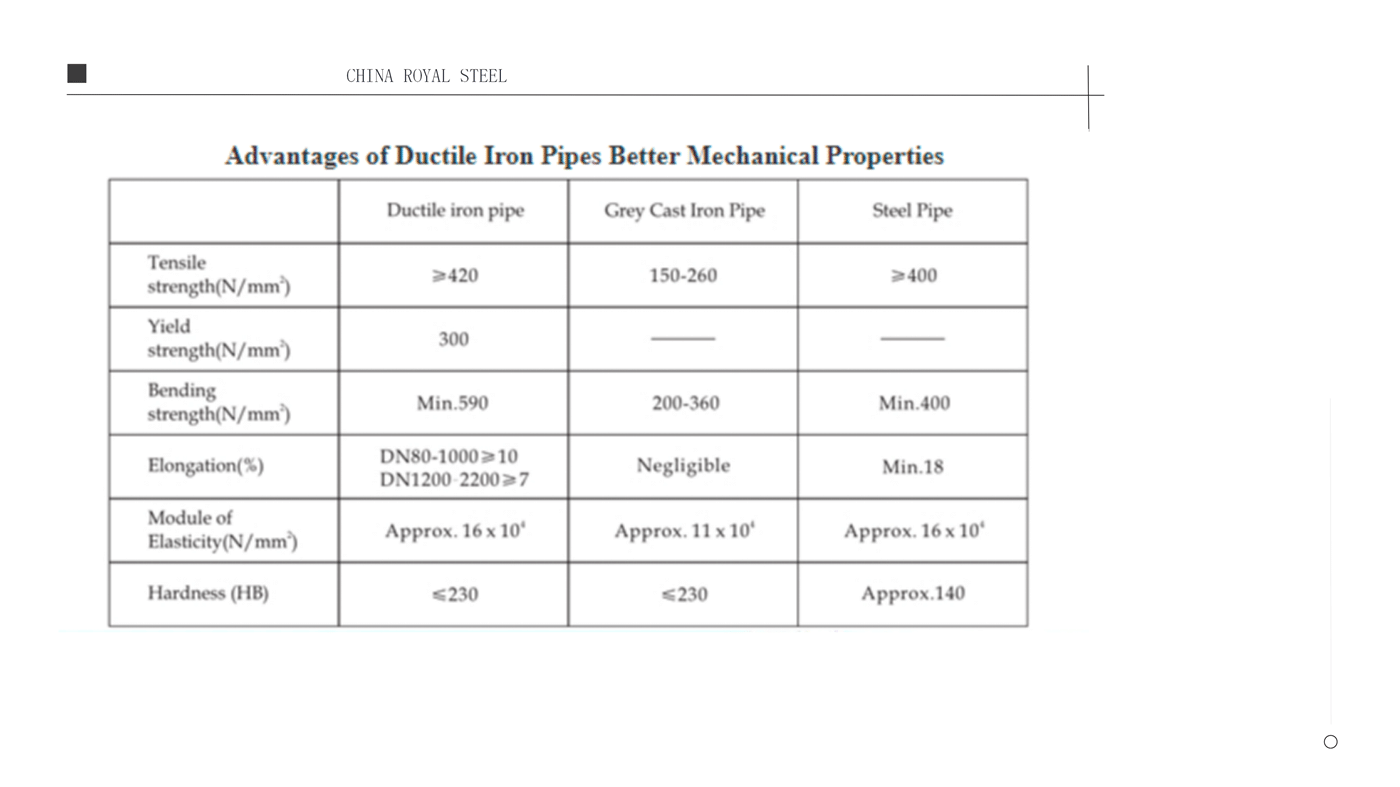

Ọkpụkpụ ígwè ndị ahụ siri ike nke a makwaara dị ka ígwè ductile ma ọ bụ ọkpọkọ ígwè nkedo nwere ike nke ígwè na ike nke ígwè. Graphite dị n'ụdị okirikiri (ọkwa 6 - 7) nwere ogo spheroidization nke 1 - 3 yana ọnụego ≥80%, nke nwere ike imeziwanye akụrụngwa akụrụngwa. Mgbe ọgwụgwọ okpomọkụ gasịrị, microstructure bụ nke kachasị ferrite na obere pearlite, nke nwere ezigbo nkwụsị na-eyi na arụmọrụ dị elu.

| Enwere ike ịhazi ngwaahịa nkọwapụta niile dịka ihe ndị ahịa chọrọ | |

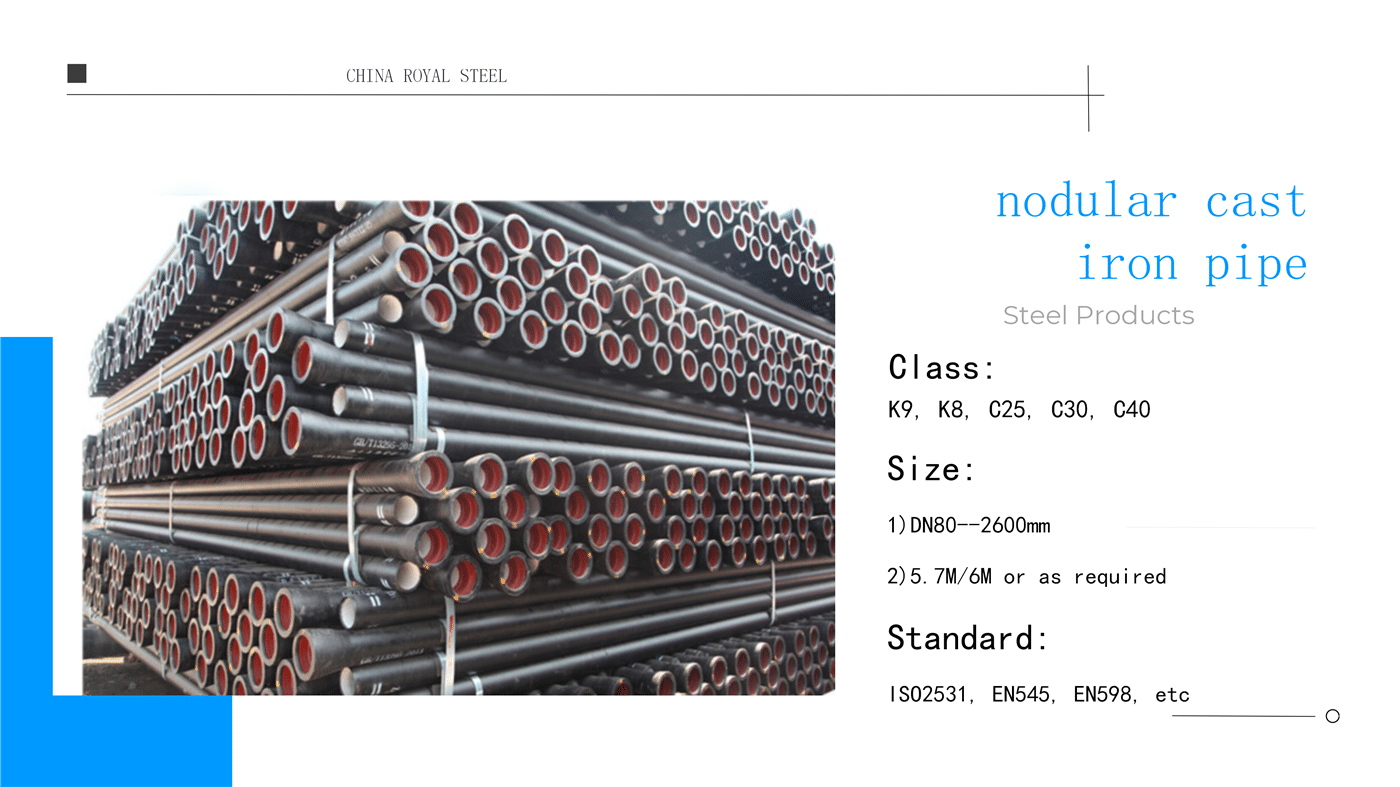

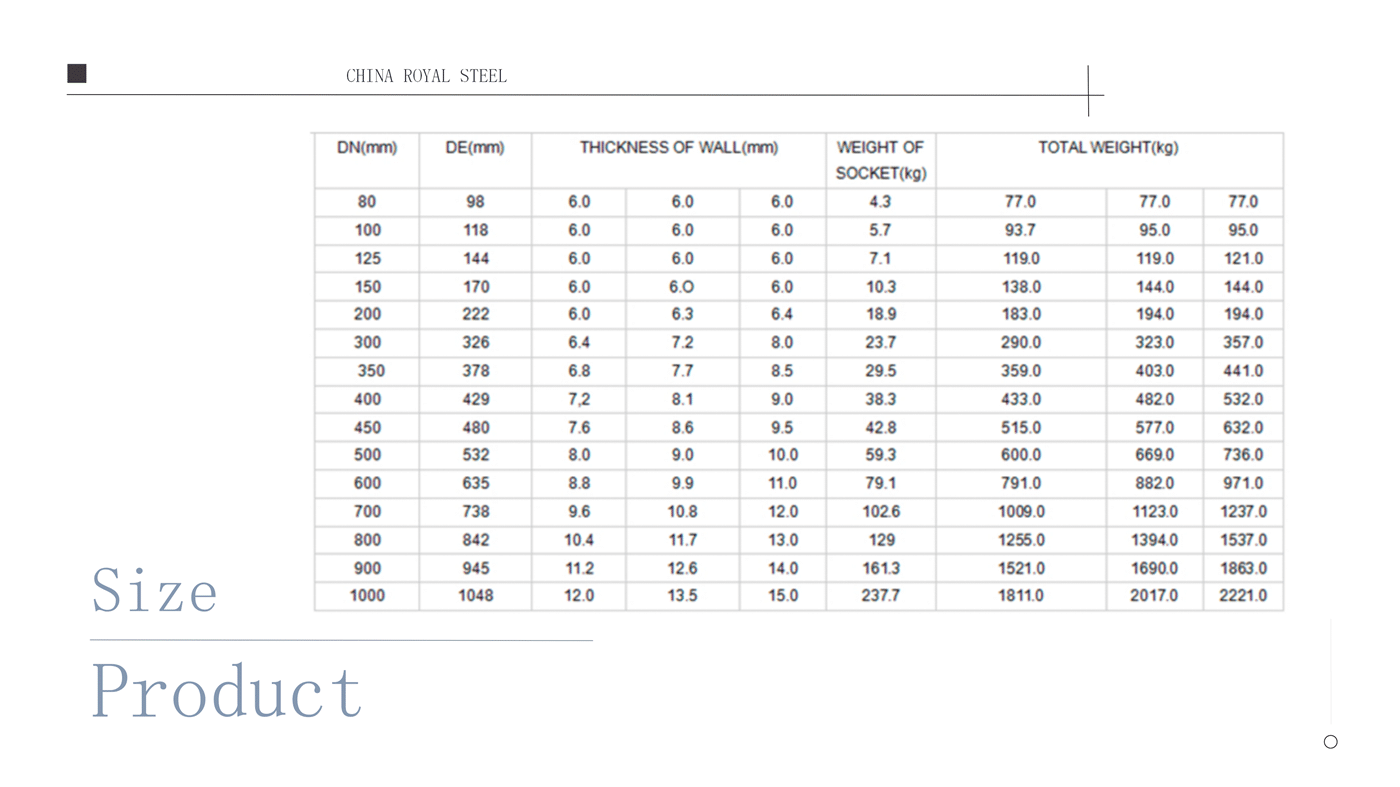

| 1. Nha | 1)DN80 ~ 2600mm |

| 2) 5.7M / 6M ma ọ bụ dị ka achọrọ | |

| 2. Ọkọlọtọ: | ISO2531, EN545, EN598, wdg |

| 3.Material | Ihe nkedo Ductile Iron GGG50 |

| 4. Ebe ụlọ ọrụ anyị | Tianjin, China |

| 5. Ojiji: | 1) Mmiri obodo |

| 2) ọkpọkọ ntụgharị | |

| 3) ugbo | |

| 6. Mkpuchi ime: | a). Ụgbọ mmiri simenti Portland b). Ihe mkpuchi simenti na-eguzogide sulfate c). Ngwunye igwe simenti dị elu-aluminom d). Fusion bonded epoxy mkpuchi e). Ihe osise epoxy mmiri f). Ihe osise bitumen ojii |

| 7. Mkpuchi Mpụga: | . Ihe osise zinc + bitumen (70microns). . Fusion bonded epoxy mkpuchi c). Zinc-aluminom alloy + ihe osise epoxy mmiri |

| 8. Ụdị: | Agbadoro |

| 9. Ọrụ nhazi | Ịgbado ọkụ, Ehulata, Punching, Decoiling, Ịcha |

| 10. MOQ | 1 Tọn |

| 11. Nnyefe: | Ngwunye, na nnukwu, |

1.Resistance na nrụgide dị n'ime: Nrụgide imewe dị elu, na nrụgide mgbawa dị okpukpu atọ nke nrụgide ọrụ, nke nwere ike ime ka nchekwa dị mma karịa ihe ndị ọzọ.

2.Resistance na nrụgide Mpụga: Ike dị elu nke ọkpọkọ na-enye ohere ntinye ntụkwasị obi na nke akụ na ụba, ebe ọ bụ na ha anaghị achọ akwa akwa pụrụ iche ma ọ bụ mkpuchi mkpuchi.

3.Inner mgbochi corrosion oyi akwa: ezigbo, inogide na mmiri ọ drinkingụ ,ụ dị mma mkpuchi ciment ngwa agha lining spun na ISO 4179.

4.Protective oyi akwa: Zinc spraying (≥130 g / m2, ISO 8179) na chlorinated resin agba, na-enye mma corrosion iguzogide. A na-enwetakwa ya na akwa akwa zinc kariri ma ọ bụ ya na mkpuchi zinc-aluminom mgbe ndị ahịa rịọrọ.

Atụmatụ

Ọkpụkpụ ígwè ductile, ụdị nkedo ígwè ọkpọkọ, jikọta iheike nke ígwèya naike nke ígwè. A na-achịkwa Spheroidization naọkwa 1-3(ọnụego ≥80%) iji kwalite akụrụngwa akụrụngwa. Ọkpọkpọ annealed atụmatụ aferrite matrix nwere obere pearlite, na-enye ezigbo nguzogide corrosion, ductility, arụ ọrụ akara, na ntinye dị mfe.

A na-ekesa ọnụ ọgụgụ graphite nodular na ferrite na pearlite matrix. Ọnụ ego nke ferrite na pearlite na nhazi matriks na-adabere na dayameta aha na elongation chọrọ. Ọnụ ego pearlite na obere dayameta anaghị adịkarị karịa 20%, ebe na nnukwu dayameta a na-achịkwa ya na ihe dịka 25%.

Ngwa

Ọkpụkpụ ígwè ductile dabara adaba maka mmiri a na-eri anụ (BS EN 545) na nsị (BS EN 598) sistemụ nwere dayameta sitere na 80-1600 mm. Ha dị mfe ịbanye, enwere ike itinye ha n'ọrụ na ọnọdụ ihu igwe niile, ugboro ugboro na-enweghị azụ azụ pụrụ iche, ma na-enye nnukwu nchekwa nchekwa na mgbanwe zuru oke iji gbanwee na mmegharị ala, ya mere a na-atụ aro ya maka iji pipeline dị iche iche.

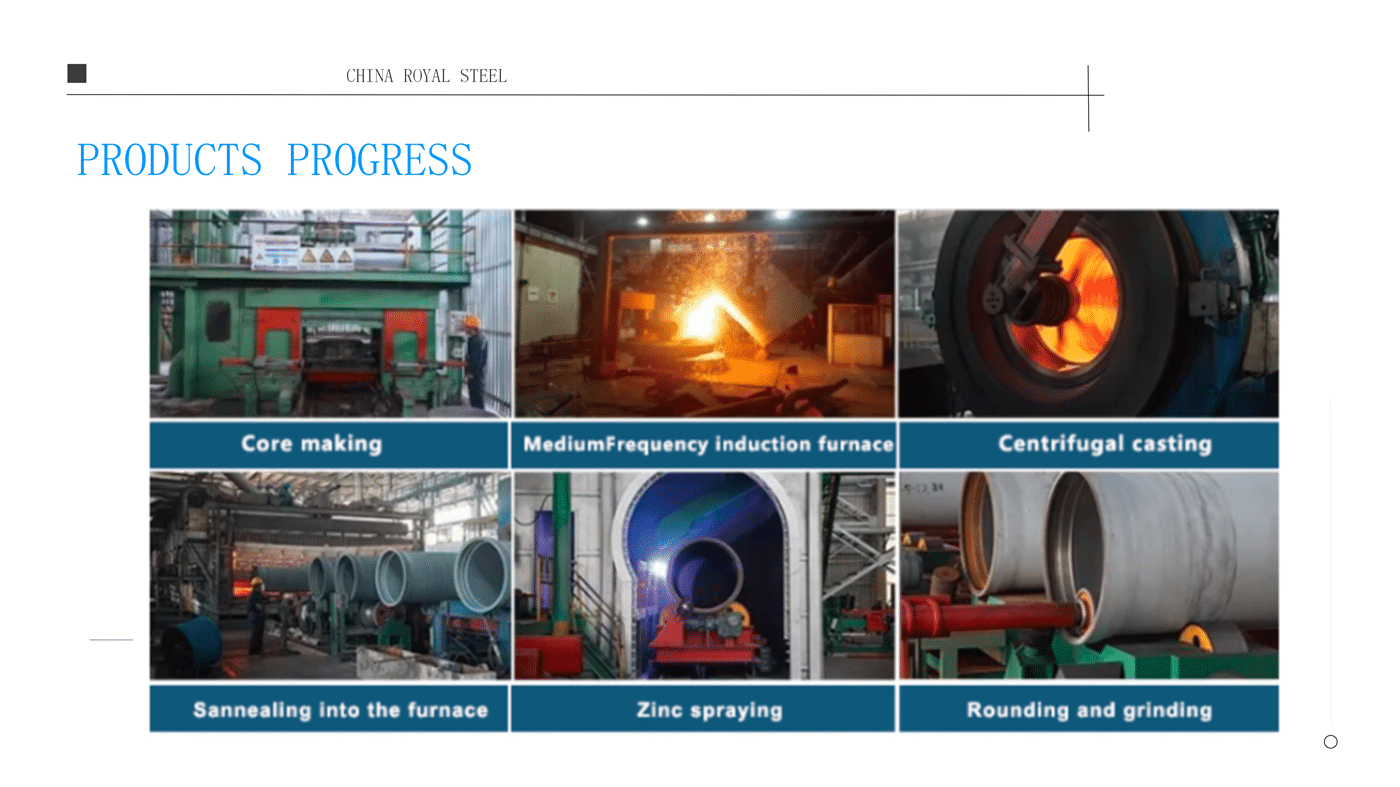

Usoro mmepụta

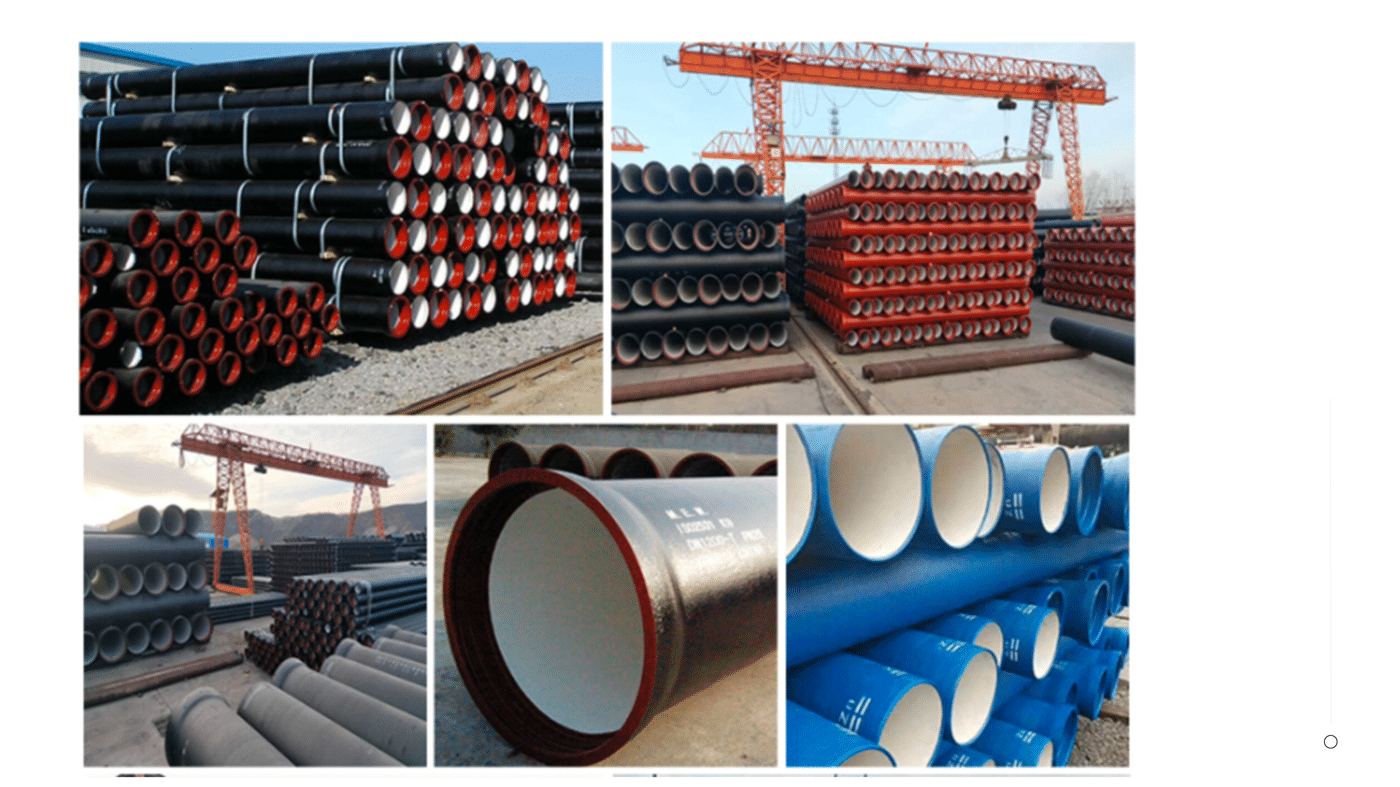

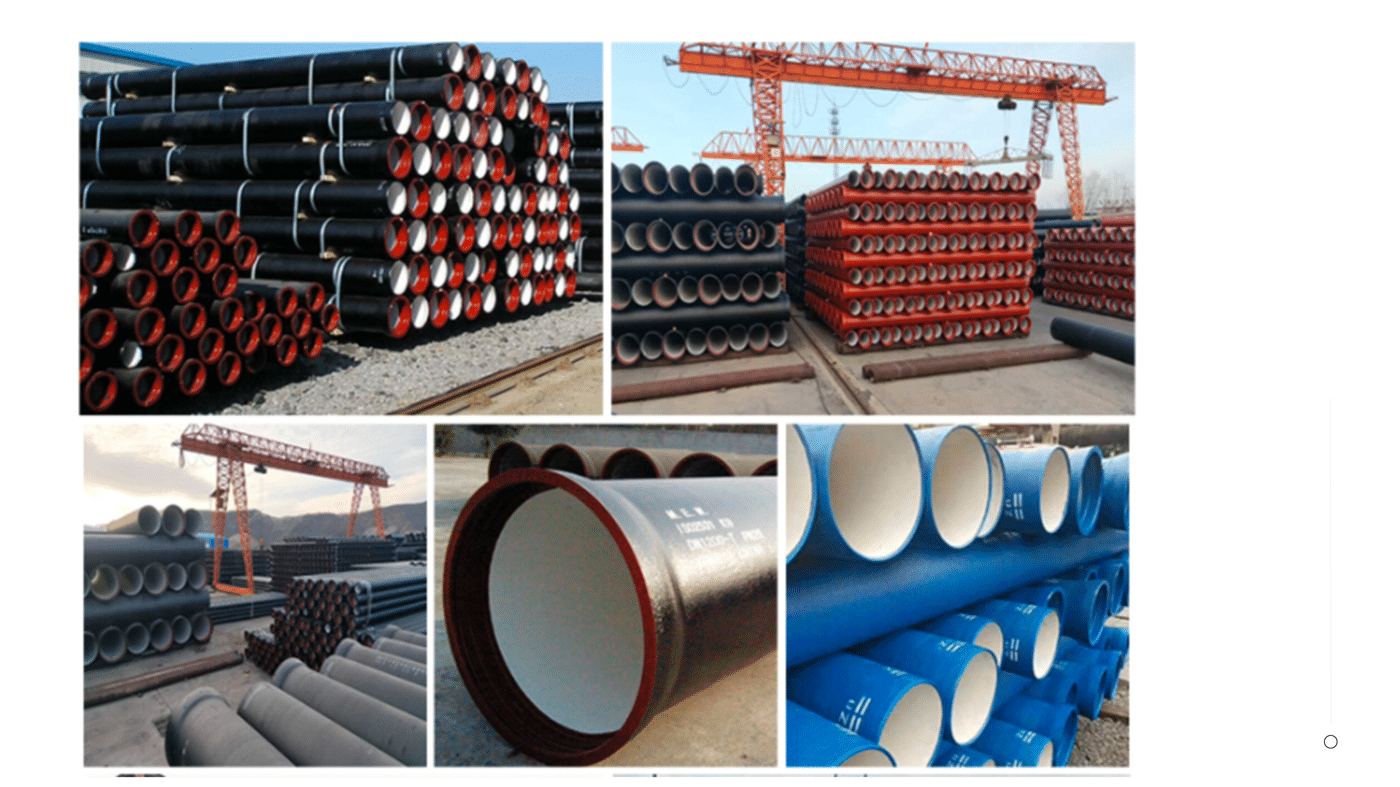

Nkwakọ ngwaahịa & Mbupu

FAQ

-

Kedu ka m ga-esi nweta ngụ akwụkwọ?

Hapụ anyị ozi, anyị ga-aza ozugbo. -

Ị ga-enyefe n'oge?

Ee, anyị na-ahụ na ngwaahịa dị elu na nnyefe n'oge. Ime ihe n'eziokwu bụ isi ụkpụrụ anyị. -

Enwere m ike nweta sample tupu ịtụ?

Ee, ihe nlele na-abụkarị n'efu ma enwere ike imepụta ya dabere na nlele gị ma ọ bụ eserese nka. -

Kedu usoro ịkwụ ụgwọ gị?

Ọ na-adịkarị,30% nkwụnye egona nguzozi a kwụrụ megide B/L. -

Ị na-anabata nyocha nke ndị ọzọ?

Ee, anyị na-anabata nke ọma nyocha ndị ọzọ. -

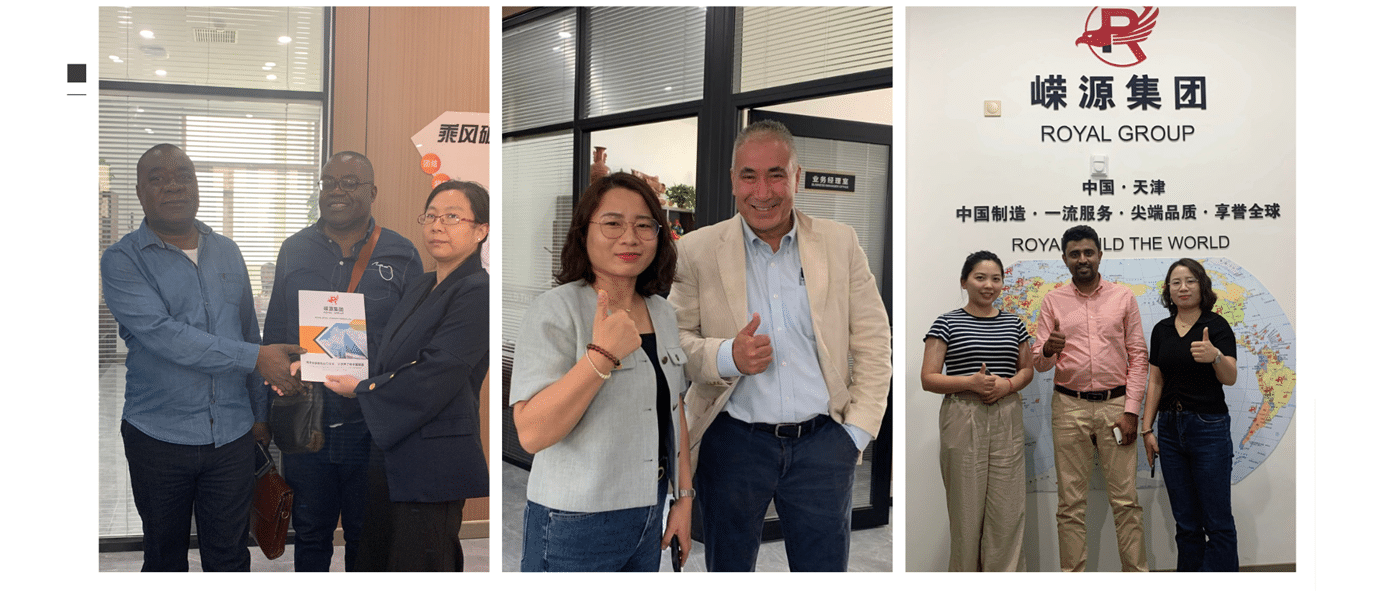

Kedu otu anyị nwere ike isi tụkwasị ụlọ ọrụ gị obi?

Anyị nwere ahụmahụ afọ dị ka onye na-eweta ọla edo na ụlọ ọrụ ígwè. Isi ụlọ ọrụ anyị dị na Tianjin, anyị na-anabata nkwenye ma ọ bụ nyocha ọ bụla.