Onye Na-ebunye China Ihe Mgbaaka Aluminom Hexagon nke A Na-emepụta Ihe nke 12mm Ogologo Hexagon Ogwe 2016 astm 233

Nkọwa Ngwaahịa

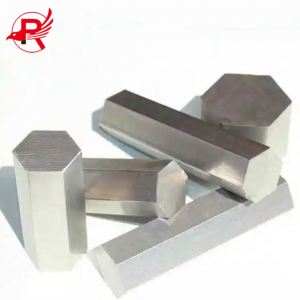

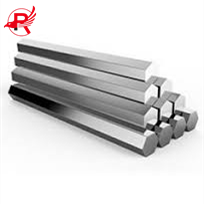

Mkpanaka aluminom nke dị n'ime hexagonal bụ ngwaahịa aluminom nke dị n'ụdị prism nke dị n'ime hexagonal, nke bụ ihe a na-ejikarị eme ihe n'ụlọ ọrụ mmepụta ihe.

Mkpanaka aluminom nke nwere hexagonal nwere njirimara nke ịdị arọ dị mfe, ezigbo nkwụsi ike, ike dị elu na ezigbo njikwa, a na-ejikwa ya nke ọma dị ka ihe na-ekpo ọkụ na ihe owuwu na ngwa eletrọnịkị na eletriki.

N'ihi njirimara nke nhazi hexagonal, ọ dị mma nke ukwuu maka imepụta akụkụ na ebu nke ụdị dị iche iche.

Nkọwapụta

N'ime ụlọ ọrụ mmepụta igwe, a na-ejikarị ya emepụta ọtụtụ ihe eji egbu stampụ; na nhazi ngwaike, a na-eji ya eme ngwaọrụ ígwè dị iche iche, paịpụ na akụkụ pụrụ iche dị iche iche; na ụlọ ọrụ ụgbọala, enwere ike iji ya maka sistemụ oyi dị ka blọk injin na drum brek. Efere esemokwu dị na ya; na mgbakwunye, enwere ike iji ya dị ka ihe ọgwụgwọ mgbochi corrosion maka akụrụngwa kemịkalụ, wdg.

Ngwa

1. Dabara adaba maka ngwaahịa eletrọniki na eletriki dị ka ihe ndị na-ekpo ọkụ ma ọ bụ akụkụ nhazi, dị ka radiators, evaporators, condensers na ngwaọrụ ndị ọzọ na-ekpo ọkụ.

2. A na-etinye ya na sistemụ oyi nke blọk injin n'ụlọ ọrụ ụgbọala na efere esemokwu dị na drum brek; enwere ike iji ya dị ka ihe eji agwọ corrosion na akụrụngwa ụlọ ọrụ kemịkalụ.

3. Ọ nwere ike dochie akụkụ ọla kọpa dị ka ihe na-agbaze n'oge ịgbado ọkụ, dịka: isi ígwè na-agbaze ọkụ, ihe na-agbaze ọkụ, waya na-agbaze, bọọlụ na-agbaze wdg.

4. Enwere ike iji ya kama imechi ihe eji arụ ọrụ maka akụkụ ígwè.

Ihe ndị a na-eji aluminom alloy 6061 eme ihe atụ iji kọwaa:

6061 Aluminom Alloy

Aluminom 6061 alloy bụ alloy a na-agwọ okpomọkụ nke nwere ezigbo nhazi, ike ịgbado ọkụ, ike igwe, na ike dị ọkara, ọ ka nwekwara ike ịnọgide na-arụ ọrụ nke ọma mgbe emechara ya.

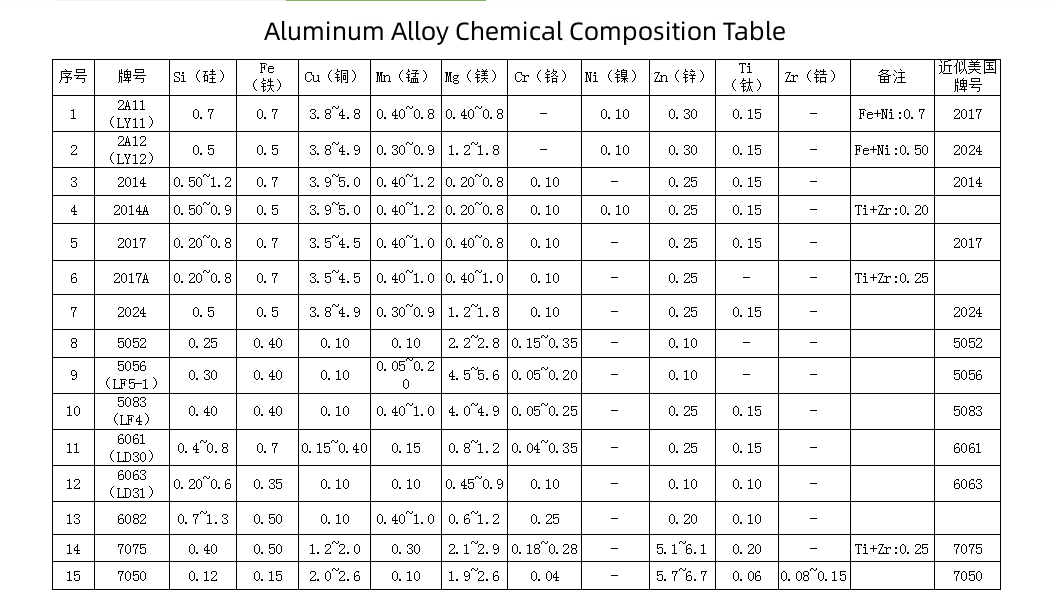

Ngwakọta kemịkalụ nke aluminom 6061 (%):

Cu: 0.15 ~ 0.4 Mn: 0.15 mg: 0.8 ~ 1.2Zn: 0.25 Cr: 0.04 ~ 0.35 Ti: 0.15 Si: 0.4 ~ 0.8 Fe: 0.7 Al: itule

Isi ojiji: A na-eji ya eme ihe n'ọtụtụ akụkụ ụlọ ọrụ mmepụta ihe dị iche iche nke chọrọ ike na oke nguzogide nchara, dịka gwongworo mmepụta, ụlọ elu, ụgbọ mmiri, tram, na ụgbọ okporo ígwè. Njirimara alloy aluminum 6061:

Ike kachasị elu nke alloy aluminom 6061 bụ 124MPa, ike mmepụta tensile bụ 5.2MPa, ọnụego ogologo bụ 25.0%, modulus nke elasticity bụ 68.9 GPa, ike kachasị elu nke ịgbagọ bụ 28MPa.

A na-ejikarị 6061 eme ihe n'ihe ndị e ji arụ ọrụ n'elu ikuku, gwongworo, ụlọ elu, paịpụ mmiri, ụgbọ mmiri, ụgbọelu, ụgbọelu, nchekwa na ngwa ndị ọzọ e ji arụ ọrụ n'elu ụlọ nke chọrọ ike, ịgbado ọkụ na iguzogide nchara.

Uru ndị a bụ 6061 aluminum alloy: 1. Aluminom siri ike nke a pụrụ ịgwọ n'ọkụ. 2. Njirimara igwe dị mma. 3. Ọ dị mma iji ya. 4. Ọ dị mfe nhazi, ọ na-eguzogide iyi nke ọma. 5. Ọ na-eguzogide nchara nke ọma na ọ na-eguzogide oxidation.

A na-ejikarị 6061 aluminum alloy eme ihe n'ihe ndị dị n'ime ụgbọelu, gwongworo, ụlọ elu, paịpụ mmiri, ụgbọ mmiri, ụgbọelu, ụgbọelu, nchekwa na ihe ndị ọzọ e ji arụ ụlọ nke chọrọ ike, ịgbado ọkụ na ebe a na-eguzogide nchara. Dịka ọmụmaatụ: akụkụ ụgbọelu, gia na shaft, akụkụ fuse, shaft na gia ngwa, akụkụ nchekwa nke valvụ jump, turbines, igodo, wdg.

Ọ bụ alloy A-Mg-Si nke nwere ike dị ọkara, ezigbo ike na-agbanwe agbanwe ma na-eguzogide nchara dị mma. Karịsịa, ọ dịghị enwe ike ịgbawa nchara nrụgide, ike ịgbado ya dị mma, iguzogide nchara na ịrụ ọrụ oyi dị mma, ọ bụ ụdị ojiji sara mbara. Alloy na-ekwe nkwa nke ukwuu. Enwere ike ịgbado ya ma tee ya agba, a pụkwara iji enamel tee ya, nke dabara adaba maka ihe ịchọ mma ụlọ. O nwere obere Cu, yabụ ike ya dị elu karịa nke 6063, mana ọ na-enwe mmetụta maka imenyụ ya.

3, Àgwà na Usoro Mmezi nke Ngalaba Ụgbọ okporo ígwè:

Ọ dịkwa elu karịa 6063. Enweghị ike ime ka ikuku gwụchaa mgbe e wepụsịrị ya, ọ dịkwa mkpa ka a rụgharịa ya ma gbanyụọ ya iji nweta ike ka mma.

Isi ihe mejupụtara ọla edo Taiwan 6061 bụ magnesium na silicon, ha na-etolite usoro Mg2Si. Ọ bụrụ na o nwere ụfọdụ manganese na chromium, ọ nwere ike iwepụ mmetụta ọjọọ nke ígwè; mgbe ụfọdụ, a na-agbakwunye obere ọla kọpa ma ọ bụ zinc iji melite ike nke alloy ahụ.

Ike na-enweghị ibelata oke nguzogide nchara ya; enwere obere ọla kọpa n'ime ihe na-eduzi iji belata mmetụta ọjọọ nke titanium na ígwè na conductivity; aluminom ma ọ bụ titanium nwere ike ime ka ọka ahụ dị ọcha ma chịkwaa nhazi recrystallization;

Iji mee ka igwe dịkwuo mma, enwere ike itinye lead na bismuth. Ngwọta siri ike nke Mg2Si dị na aluminom na-eme ka alloy ahụ nwee ọrụ nke ime ka ịka nká sie ike.

6061-T651 bụ ihe mejupụtara alloy 6061. Ọ bụ ngwaahịa alloy aluminom dị elu nke a na-emepụta site na ọgwụgwọ okpomọkụ na usoro ịgbatị tupu oge eruo. Ọ bụ ezie na ike ya enweghị ike iji ya tụnyere usoro 2XXX ma ọ bụ usoro 7XXX, alloy magnesium na silicon ya pụrụ iche.

O nwere ọtụtụ ihe onwunwe, arụmọrụ nhazi dị mma, njirimara ịgbado ọkụ dị mma na njirimara electroplating, ezigbo nguzogide corrosion, ike dị elu na enweghị mgbanwe mgbe nhazi gasịrị, ihe dị oke arọ na-enweghị ntụpọ na mfe ịcha ọcha, dị mfe itinye ihe nkiri agba, mmetụta oxidation magburu onwe ya na atụmatụ ndị ọzọ dị mma.

4, Chaatị usoro mmepụta ụgbọ okporo ígwè:

Ịgbaze → ịkpụ → mkpara ịkpụ osisi → ime ka mkpanaka aluminom dị n'otu → oyi, mkpara ịsa ákwà → mkpara aluminom banye n'ụlọ nkwakọba ihe.

Ajụjụ Ndị A Na-ajụkarị

1. Kedu otu m ga-esi nweta nkọwa n'aka gị?

I nwere ike izipu anyị ozi, anyị ga-azakwa ozi ọ bụla n'oge.

2.Ị ga-ebuga ngwongwo n'oge?

Ee, anyị na-ekwe nkwa inye ngwaahịa kacha mma na nnyefe n'oge. Ikwesị ntụkwasị obi bụ echiche ụlọ ọrụ anyị.

3. Enwere m ike ịnweta ihe nlele tupu iwu?

Ee, n'ezie. Ọtụtụ mgbe, ihe nlele anyị bụ n'efu, anyị nwere ike imepụta site na ihe nlele gị ma ọ bụ eserese teknụzụ.

4. Kedu usoro ịkwụ ụgwọ gị?

Oge ịkwụ ụgwọ anyị na-akwụkarị bụ 30% nkwụnye ego, ma ọ ga-abụ na anyị ga-akwụ ụgwọ megide B/L. EXW, FOB, CFR, na CIF.

5. Ị na-anabata nyocha nke ndị ọzọ?

Ee anyị nabatara nke ọma.

6. Kedu ka anyị si atụkwasị ụlọ ọrụ gị obi?

Anyị bụ ọkachamara n'azụmahịa ígwè ruo ọtụtụ afọ dịka onye na-ebunye ọla edo, isi ụlọ ọrụ anyị dị na mpaghara Tianjin, anyị na-anabata gị inyocha ya n'ụzọ ọ bụla.