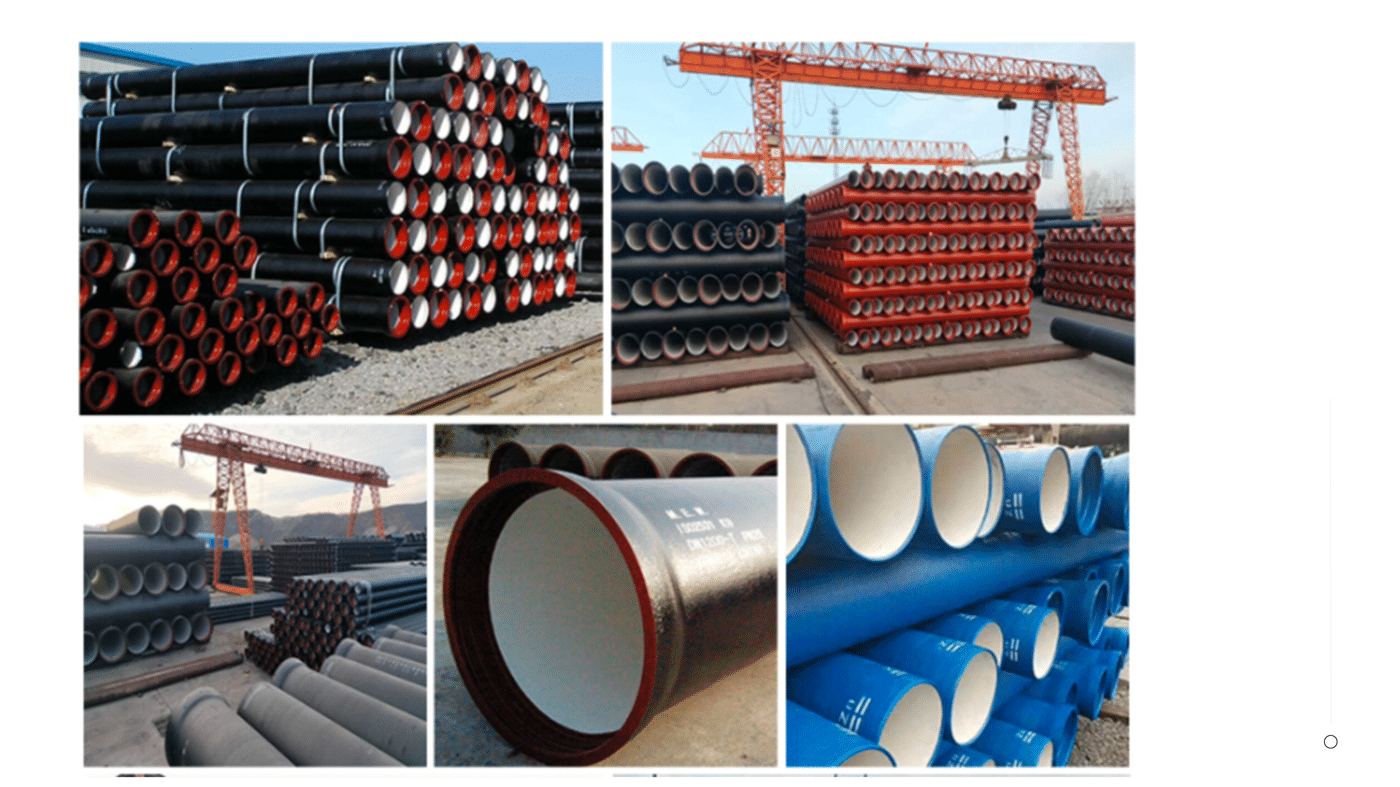

Ahịa ụlọ ọrụ 2024 Hot ire C25 Ọkwa Ductile Iron Pipe K8 K9 900mm Ductile Iron Pipe Ciment Lineed Pipe

Nkọwa ngwaahịa

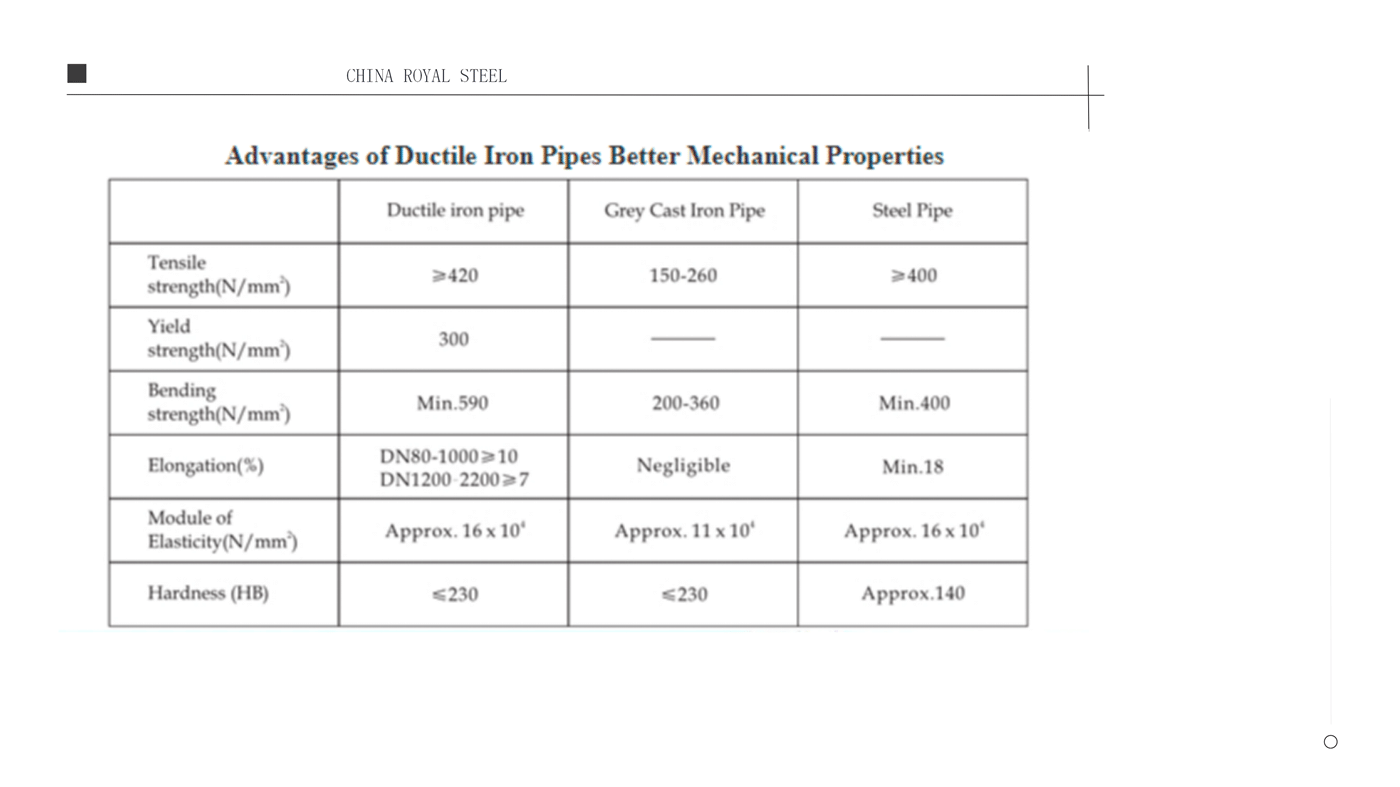

Nodular nkedo ígwè ọkpọkọs bụ nnoo ductile ígwè ọkpọkọ, nke nwere ọdịdị nke ígwè na Njirimara nke ígwè, n'ihi ya aha ha. Graphite dị na ọkpọkọ ígwè ductile dị n'ụdị okirikiri, yana ogo 6-7 n'ozuzu ya. N'ihe banyere ịdị mma, a chọrọ ka a na-achịkwa ọkwa spheroidization nke ọkpọkọ ígwè nkedo na ọkwa 1-3, yana ọnụego spheroidization nke ≥ 80%. Ya mere, a na-emeziwanye ihe eji arụ ọrụ nke ihe ahụ n'onwe ya, na-enwe ihe dị mkpa nke ígwè na ihe ndị dị na ígwè. Mgbe annealing gasịrị, microstructure nke ductile iron pipes bụ ferrite na obere pearlite, nke nwere ezigbo ihe eji arụ ọrụ, ya mere a na-akpọkwa ya nkedo.ígwè ígwè ọkpọkọ.

| Enwere ike ịhazi ngwaahịa nkọwapụta niile dịka ihe ndị ahịa chọrọ | |

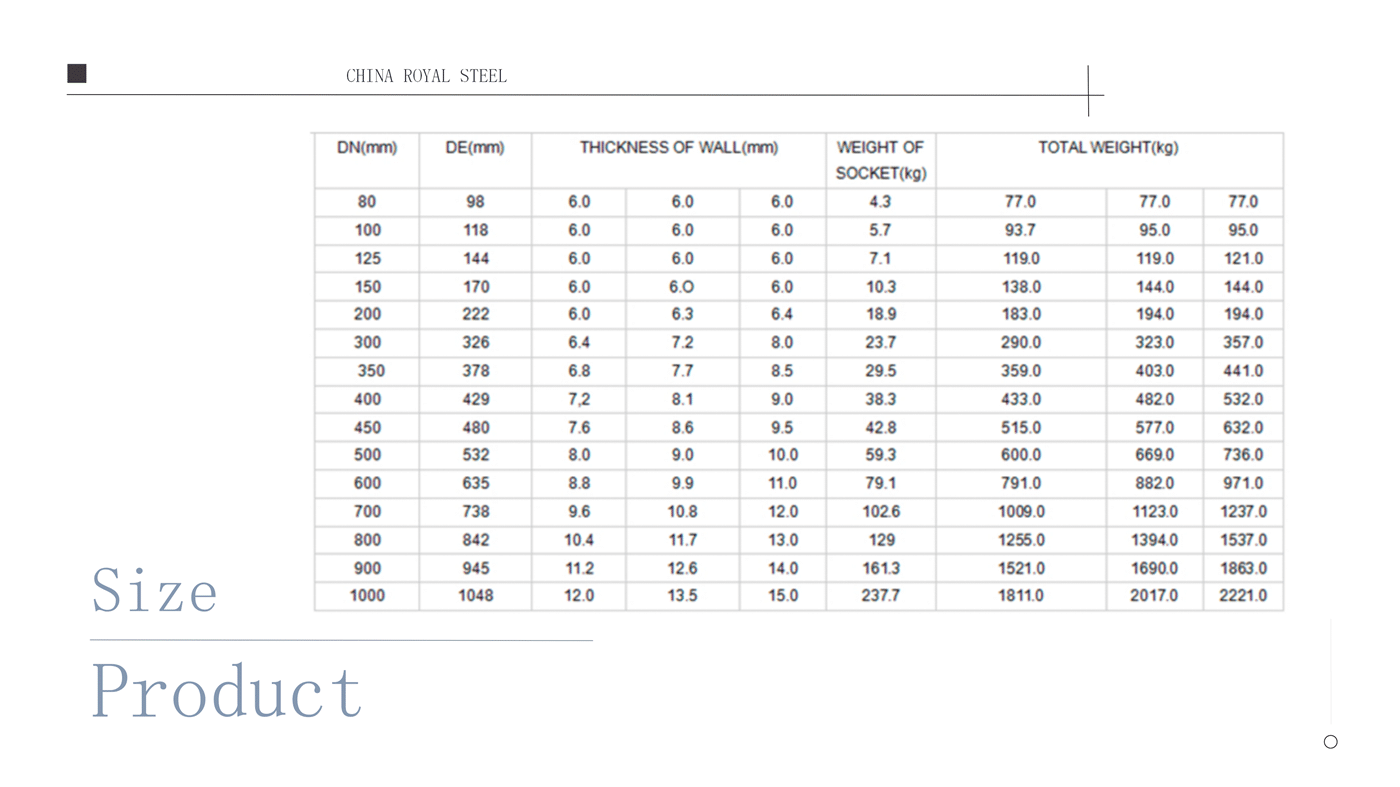

| 1. Nha | 1)DN80 ~ 2600mm |

| 2) 5.7M / 6M ma ọ bụ dị ka achọrọ | |

| 2. Ọkọlọtọ: | ISO2531, EN545, EN598, wdg |

| 3.Material | Ihe nkedo Ductile Iron GGG50 |

| 4. Ebe ụlọ ọrụ anyị | Tianjin, China |

| 5. Ojiji: | 1) Mmiri obodo |

| 2) ọkpọkọ ntụgharị | |

| 3) ugbo | |

| 6. Mkpuchi ime: | a). Ụgbọ mmiri simenti Portland b). Ihe mkpuchi simenti na-eguzogide sulfate c). Ngwunye igwe simenti dị elu-aluminom d). Fusion bonded epoxy mkpuchi e). Ihe osise epoxy mmiri f). Ihe osise bitumen ojii |

| 7. Mkpuchi Mpụga: | . Ihe osise zinc + bitumen (70microns). . Fusion bonded epoxy mkpuchi c). Zinc-aluminom alloy + ihe osise epoxy mmiri |

| 8. Ụdị: | Agbadoro |

| 9. Ọrụ nhazi | Ịgbado ọkụ, Ehulata, Punching, Decoiling, Ịcha |

| 10. MOQ | 1 Tọn |

| 11. Nnyefe: | Ngwunye, na nnukwu, |

1.Internal Pressure Resistance: Ductile iron pipe nwere ike nke ígwè na siri ike nke ígwè ọ bụ nhọrọ kacha mma. A na-etinye nrụgide na-arụ ọrụ dị elu, na mgbawa mgbawa ruru ugboro atọ nke nrụgide ọrụ.

2.External Pressure Resistance: Nguzogide nrụgide dị elu pụtara obere ihe ndina ma ọ bụ akwa akwa pụrụ iche chọrọ, na-eme ka ntinye gị dị mfe ma dịkwuo ọnụ.

3.Inner Anti-corrosion Layer: A na-eji ụrọ ciment kpuchie ọkpọkọ centrifugally dịka ISO 4179 si dị maka ngwa mmiri ọ drinkingụ drinkingụ. Usoro a na-emepụta akwa dị nro, nke siri ike nke na-echebe mmiri ọ drinkingụ drinkingụ na-adịghị agbaze ma ọ bụ nchara.

4.Protective Layer: Zinc spraying (≥130 g / m², ISO 8179) na chlorinated resin agba na-enyere nchebe ka mma megide corrosion. Enwere ike ịnye akwa akwa akwa akwa zinc ma ọ bụ mkpuchi zinc-aluminom dịka nkọwapụta ndị ahịa si dị.

Atụmatụ

Ọkpụkpụ ígwè ductilebụ ụdị ọkpọkọ nkedo. A na-arụpụta ọkpọkọ ígwè ductile na ọkwa 1-3 nke spheroidization (Spheroidizationrate> 80%) iji meziwanye ihe arụ ọrụ site n'iji ike nke ígwè na ike nke ígwè mee ihe. Ọkpụkpọ annealed nwere ihe owuwu ferrite na obere pearlite, ma nwee ezigbo nguzogide corrosion, ductility, arụmọrụ akara na mfe maka ntinye. Ha na-ahụta ojiji dị ukwuu na ntinye mmiri, nnyefe gas, na njem mmanụ na obodo na ụlọ ọrụ.

Spherical graphite bụ matriks nke ferrite na pearlite gbara ya gburugburu. Ọnụ ọgụgụ nke pearlite na ferrite na-adabere n'otú ọkpọkọ na ihe elongation chọrọ: maka ọtụtụ akụkụ, obere ọkpọkọ nwere pearlite ≤20% na nnukwu ọkpọkọ ≈25%.

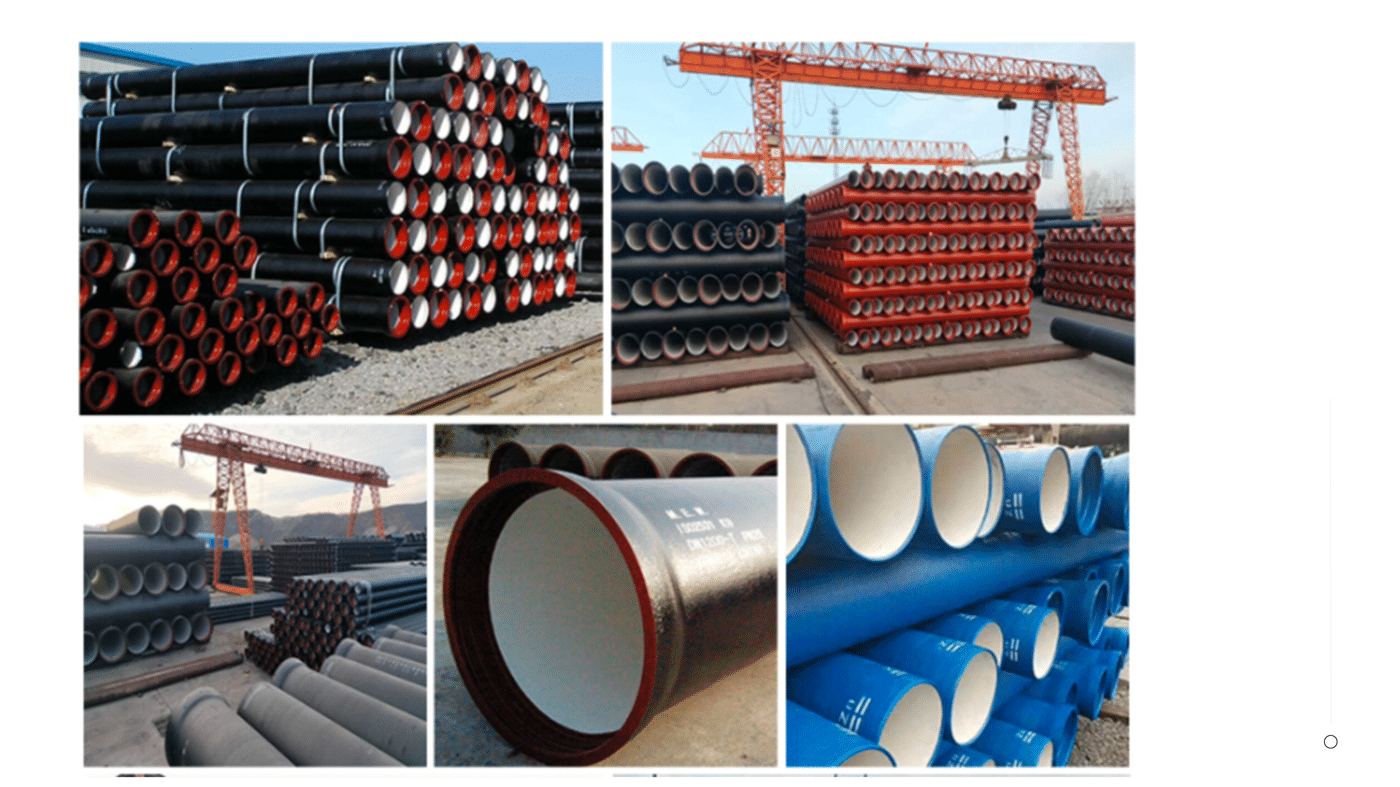

Ngwa

A na-etinye ọkpọkọ ọkpọkọ na nha site na 80 ruo 1600 mm na mmiri ọ drinkingụ drinkingụ (BS EN 545) yana na mmiri nsị (BS EN 598). Ha na-ejikọta ngwa ngwa, wụnye na ihu igwe ọ bụla, na-emekarị na-enweghị azụ azụ pụrụ iche, ma na-enye ihe nchekwa dị elu nke nwere ike ime mgbanwe zuru oke iji gbochie mmegharị ala, na-akwadebe ha nke ọma maka iji ngwa ngwa pipeline dị iche iche.

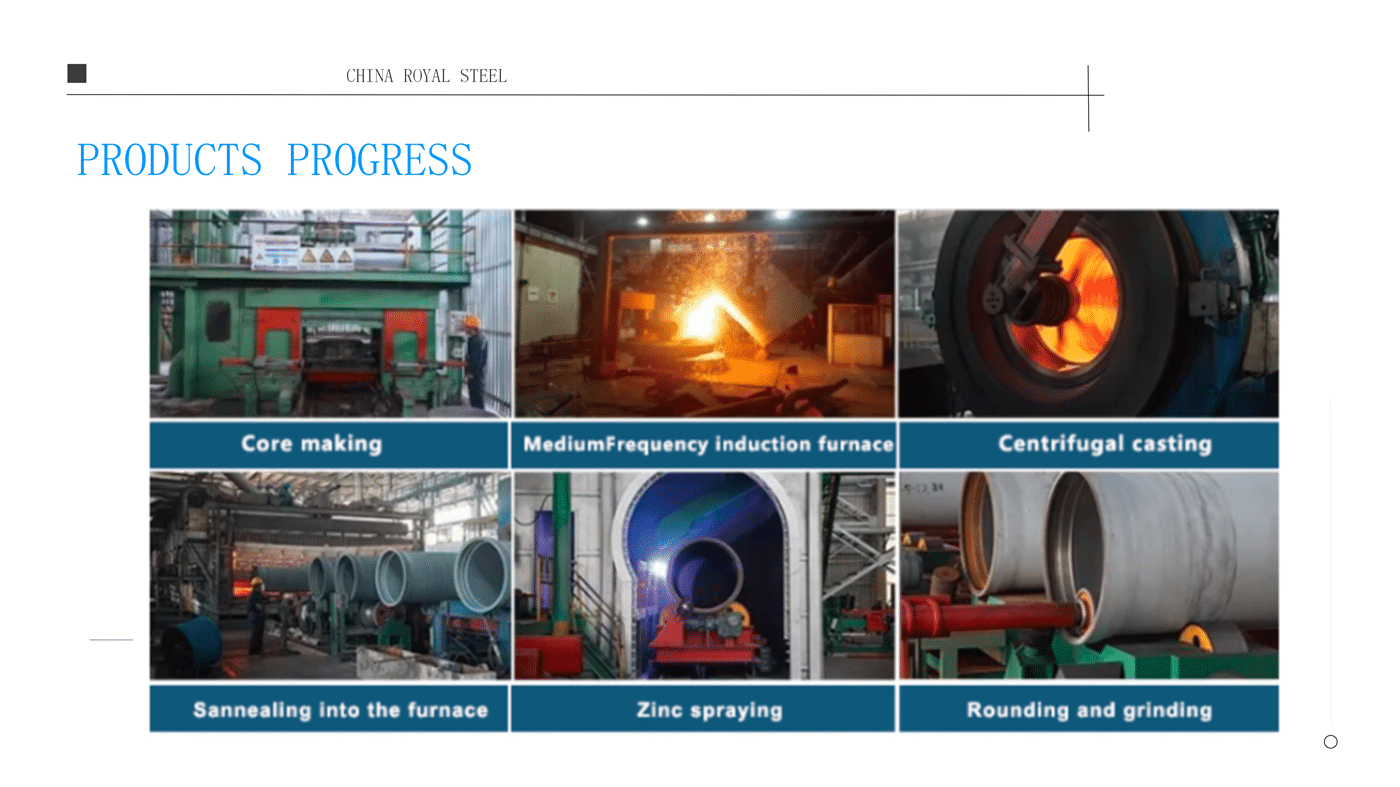

Usoro mmepụta

Nkwakọ ngwaahịa & Mbupu